High performance Carbide Cermet Inserts for stainless steel

Our Advantages JD tools co.ltd

1. Good chip control & perfect turning surface

Provides perfect turning surface of the workpiece .Excellent and reasonable Chipbreaker design, removing the chips smoothly and taking away the heat of the rubs of the workpiece.

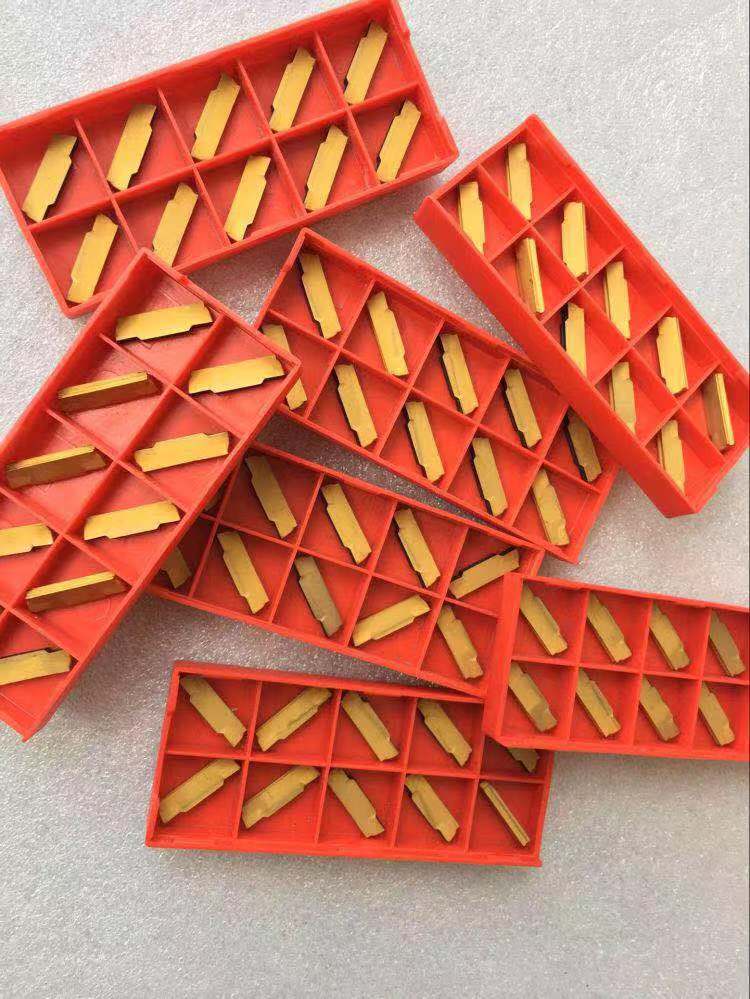

2. CVD coating ensures the high wear resistance

The layer of the CVD coating with the thickness around 8um-20um which guaranteed the high wear resistance.

3. Less tool breakage, cost down of each component

Saving costs and reducing the cost of each component to increase the profits .The high wear resistance makes the long tool life of the carbide inserts, which means you could saving more budget on purchasing the inserts.

4. Long tool life, higher production.

Long tool life means you need less time changing the inserts while machining. A reliable and safe performance every time.

Customer's case: when a insert is failed on performance:

1. Flank Wear

-Workpiece material contains high hardness chemical elements (tool steel, die steel)

Increase cutting speed if abnormal flank wear is caused by a very slow cutting speed.

Solution: Reduce cutting speed or feed rate or use more wear resistant grade

2. Crater Wear

-Workpiece material contains high hardness chemical elements

Solution: Reduce cutting speed or feed rate or use more wear resistant grade

3. Cracking

-Excessive feed rates when interrupted cutting

Solution: Reduce feed rate, Use tougher grade

Technical support and after-sale service:

1. Recommending more suitable processing parameters.

2. According to the workpiece design, material and CNC machine feed rate, cutting speed we can recommending a full set of practical scheme.

3. Suggsting more suitable model to replace the brands of Japan, Korea and so on

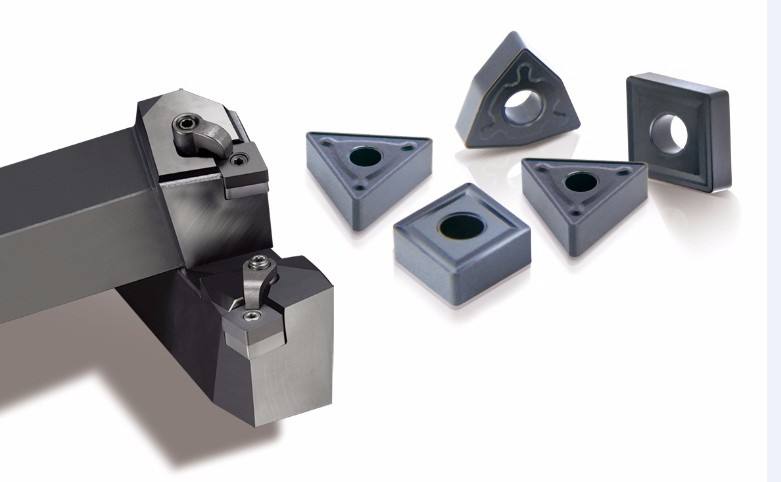

Product Description

CNC tungsten carbide inserts for turning models

1. Grade: YC330 YC331 YC332 for Steel Processing

2. Size: CNMG1204 CNMG1606 CNMG1906 CNMG2509

3. Chipbreaker: PM, GF, GM, GR, HGR

3. Standard: ISO Standard

4. Certification: ISO9001

5. Material: Tungsten Carbide

6. HS Code: 8208101900

Main products of JD tools co.ltd

|

|

||||

|

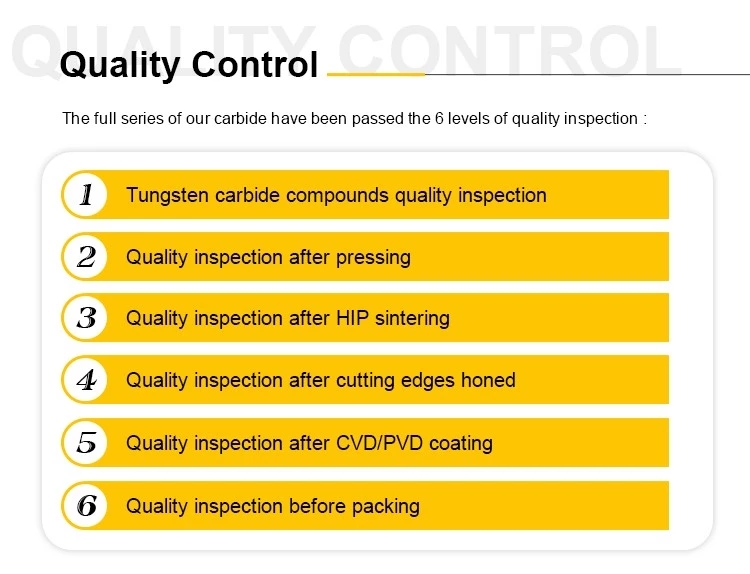

Class P Turning Grade (Steel) JD tools co.ltd |

||||

|

YC330 |

Black |

The combination of high wear resistance substrate with (MT-TiCN+thick AL2O3 +TiN )coating is suitable for finishing machining of steel at high speed. |

GC4015 UE6010 CA5515 YBC152 |

|

|

YC331 |

Black |

The combination of high strength and high toughness substrate with (MT-TiCN+thick AL2O3 + TiN )coating is the general brand of steel processing |

GC4025 UE6020 CA5025 YBC252 |

|

|

YC332 |

Black |

High-strength and plastic-resistant substrate combined with( MT-TiCN+thick AL2O3 + TiN )coating, has good toughness and resistance to plastic deformation. It is suitable for light rough machining and rough machining of steel parts. |

GC4035 UE6035 CA9025 YBC351 |

|

|

CNMG1204 |

CNMG1606 |

CNMG1906 |

CNMG2509 |

|

|

YC330/CNMG120404-GF YC331/CNMG120404-GF |

YC331/CNMG160608-GM |

YC331/CNMG190608-GM |

YC332/CNMM250924-HGR |

|

|

YC331/CNMG120404-PM |

YC331/CNMG160612-GM |

YC331/CNMG190612-GM |

||

|

YC331/CNMG120404-GM |

YC331/CNMG160612-GR |

YC331/CNMG190612-GR YC330/CNMG120404-GF |

||

|

YC331/CNMG120408-PM |

YC331/CNMG160616-GM |

YC331/CNMG190616-GM |

||

|

YC331/CNMG120408-GM |

YC331/CNMG160616-GR YC332/CNMG120404-GF |

YC331/CNMG190616-GR YC330/CNMG120404-GF |

||

|

YC331/CNMG120408-GR |

YC332/CNMG190624-GR |

|||

|

YC331/CNMG120412-PM |

YC332/CNMM190612-GR |

|||

|

YC331/CNMG120412-GM |

YC332/CNMM190616-GR |

|||

|

YC331/CNMG120412-GR |

YC332/CNMM190624-GR |

|

||

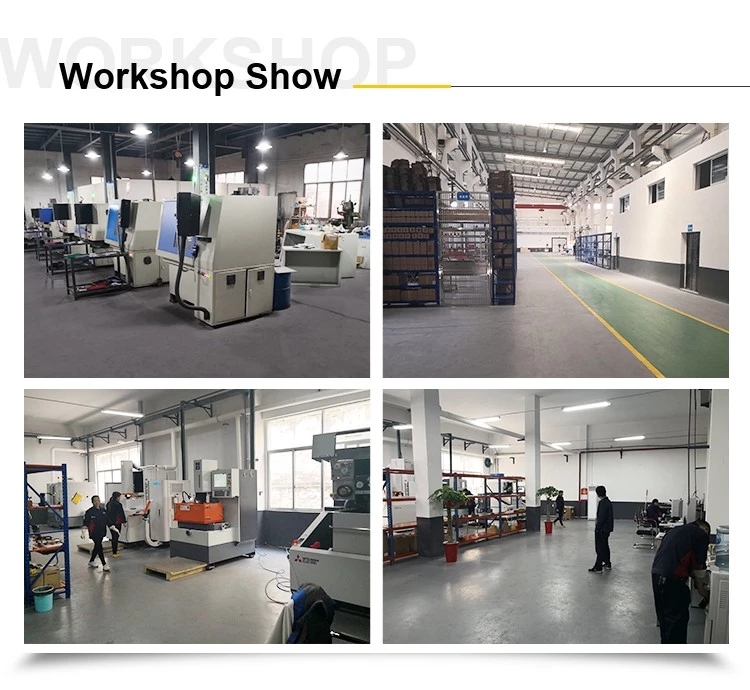

Factory show

Company team cooperation

Zhuzhou JD Carbide Tool Co.,ltd. India Exhibition

FAQ

Q: Is zhuzhou JD carbide tools co.,ltd company or factory:

A: We are carbide tools professional factory more than 17 years. we are located in zhuzhou. the best tungsten carbide tools manufacture are in China

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q:Is free shipping possible?

A: We don't offer free shipping service,but we will give you some discount if you buy large quantity products.

And we have cooperation Express Companies,can offer you the best price of shipping cost.

Q: How can I pay?

A: we accept paypal as the sample. if large amount need pay by western union or TT

A: And large amount,could 30% payment before produce, 70% balance payment before delivery,then you can get the Tracking Number

Q:Whats your MOQ?

A:we welcome your sample order to test our quality, we believe that u will find that we are the right supplier u are looking for.so no MOQ

If you are interested in our cpmpany and products, please do not hesitate to contact me:

Mr: Louis ou

Tel: +86-731-86457568

Mobile: +86-19873087993

whatsapp:+86-19873087993

We will provide our best quality and price for you.